Understanding the definition of real plies is essential for anyone involved in woodworking, construction, or design. Real plies refer to the layers of wood veneers that are bonded together to form plywood or other engineered wood products. These layers play a crucial role in determining the strength, durability, and quality of the final product. Whether you're a professional carpenter, an architect, or a DIY enthusiast, having a clear understanding of real plies can help you make informed decisions when selecting materials for your projects.

In today's construction industry, engineered wood products have become increasingly popular due to their superior performance and versatility. Real plies are at the core of these products, offering unmatched strength and stability. By exploring the intricacies of real plies, you can gain insights into how these materials are constructed and why they are preferred over traditional solid wood in many applications.

From the manufacturing process to the benefits of using real plies, this article will provide a comprehensive overview of the topic. We will also delve into the various types of plies, their applications, and the factors that influence their quality. Whether you're new to woodworking or an experienced professional, this guide will equip you with the knowledge you need to work effectively with real plies.

Read also:Who Is Jay Ma The International Student Taking Instagram By Storm

Table of Contents

- What Are Real Plies?

- History of Plies in Woodworking

- Types of Real Plies

- Manufacturing Process of Real Plies

- Factors Affecting the Quality of Real Plies

- Applications of Real Plies

- Benefits of Using Real Plies

- Comparison with Solid Wood

- Maintenance and Care of Real Plies

- Environmental Impact of Real Plies

- Future Trends in Real Plies

What Are Real Plies?

Real plies are thin layers of wood veneers that are glued together to form plywood or other engineered wood products. Each layer is typically arranged with its grain direction perpendicular to the adjacent layer, creating a cross-laminated structure. This arrangement enhances the strength and stability of the final product, making it less prone to warping or cracking compared to solid wood.

Understanding the definition of real plies involves recognizing their role in the construction of plywood and other composite materials. The term "real plies" emphasizes the use of natural wood veneers, distinguishing them from synthetic or imitation layers that may be used in some products. This distinction is important for consumers who prioritize authenticity and sustainability in their material choices.

History of Plies in Woodworking

Origins of Plywood

The concept of using layers of wood to create stronger materials dates back thousands of years. Ancient Egyptians were among the first to experiment with early forms of plywood, bonding thin sheets of wood together to create furniture and other objects. Over time, the technique evolved, and by the 18th century, European craftsmen began producing more refined versions of plywood for decorative purposes.

Modern Developments

The industrial revolution marked a significant turning point in the history of plies. Advances in machinery and adhesives made it possible to produce plywood on a large scale, making it an affordable and accessible material for construction and manufacturing. Today, real plies are used in a wide range of applications, from residential construction to aerospace engineering.

Types of Real Plies

Hardwood and Softwood Plies

Real plies can be categorized into hardwood and softwood varieties based on the type of wood used. Hardwood plies, such as those made from oak, maple, or birch, are known for their durability and aesthetic appeal. Softwood plies, derived from pine, spruce, or fir, are often used in structural applications due to their strength and affordability.

Decorative and Structural Plies

Another way to classify real plies is by their intended use. Decorative plies are designed for their appearance and are often used in furniture, cabinetry, and flooring. Structural plies, on the other hand, prioritize strength and stability, making them ideal for construction projects such as roofing, flooring, and wall panels.

Read also:Remote Iot Monitoring With Ssh Download And Configure On Raspberry Pi

Manufacturing Process of Real Plies

The manufacturing process of real plies involves several key steps, including:

- Log Selection: High-quality logs are selected and cut into thin veneers using a rotary lathe or slicing machine.

- Veneer Drying: The veneers are dried to reduce moisture content and improve bonding strength.

- Layer Assembly: The veneers are stacked with alternating grain directions and coated with adhesive.

- Pressing and Curing: The assembled layers are pressed together under high pressure and heat to cure the adhesive and form a solid panel.

This process ensures that the final product meets industry standards for strength, durability, and appearance.

Factors Affecting the Quality of Real Plies

Several factors influence the quality of real plies, including:

- Wood Species: The type of wood used affects the appearance, strength, and durability of the plies.

- Veneer Thickness: Thicker veneers generally provide greater strength, but thinner veneers can offer better flexibility.

- Adhesive Type: The choice of adhesive impacts the bond strength and resistance to moisture and heat.

- Manufacturing Standards: Compliance with industry standards ensures consistent quality and performance.

Selecting high-quality real plies requires careful consideration of these factors to ensure the best results for your project.

Applications of Real Plies

Construction Industry

In the construction industry, real plies are widely used in applications such as:

- Roofing and flooring systems

- Wall panels and sheathing

- Formwork for concrete casting

Furniture and Cabinetry

Real plies are also popular in the furniture and cabinetry industry, where they are used to create durable and attractive products such as:

- Tables and chairs

- Kitchen cabinets and countertops

- Storage units and shelving

Benefits of Using Real Plies

There are numerous advantages to using real plies in various applications:

- Strength and Stability: The cross-laminated structure of real plies provides superior strength and resistance to warping.

- Cost-Effectiveness: Real plies offer excellent value for money, especially when compared to solid wood.

- Sustainability: Using real plies helps conserve natural resources by maximizing the use of wood from each log.

These benefits make real plies an attractive option for both residential and commercial projects.

Comparison with Solid Wood

While real plies and solid wood share some similarities, there are key differences that make them suitable for different applications:

- Strength and Stability: Real plies are generally more stable and less prone to cracking or warping than solid wood.

- Cost: Solid wood tends to be more expensive than real plies, especially for high-quality species.

- Aesthetics: Solid wood is often preferred for its natural beauty and unique grain patterns, while real plies can be finished to mimic the appearance of solid wood.

Choosing between real plies and solid wood depends on the specific requirements of your project.

Maintenance and Care of Real Plies

To ensure the longevity of real plies, proper maintenance and care are essential. Here are some tips:

- Protect the surface from scratches and abrasions by using furniture pads or coasters.

- Clean the surface regularly with a damp cloth and mild detergent.

- Avoid exposing real plies to excessive moisture or direct sunlight to prevent damage.

By following these guidelines, you can extend the life of your real plies and maintain their appearance.

Environmental Impact of Real Plies

The environmental impact of real plies depends on factors such as the source of the wood, the manufacturing process, and the end-of-life disposal. Sustainable practices, such as using certified wood from responsibly managed forests and recycling waste materials, can minimize the environmental footprint of real plies.

Additionally, advancements in adhesive technology have led to the development of low-VOC (volatile organic compound) and formaldehyde-free options, further reducing the environmental impact of real plies.

Future Trends in Real Plies

The future of real plies looks promising, with ongoing innovations in materials, manufacturing processes, and applications. Some emerging trends include:

- Biocomposites: The integration of natural fibers and biodegradable materials into real plies to enhance sustainability.

- Smart Materials: The development of real plies with embedded sensors or self-healing properties for advanced applications.

- Customization: Increased demand for personalized designs and finishes to meet the unique needs of consumers.

These trends highlight the potential for real plies to play an even greater role in the future of construction and design.

Conclusion

In conclusion, understanding the definition of real plies is crucial for anyone involved in woodworking, construction, or design. Real plies offer numerous benefits, including strength, stability, and cost-effectiveness, making them a popular choice for a wide range of applications. By considering factors such as wood species, veneer thickness, and adhesive type, you can select the right real plies for your project and achieve optimal results.

We invite you to share your thoughts and experiences with real plies in the comments section below. If you found this article helpful, please consider sharing it with others who may benefit from the information. For more insights into woodworking and construction, explore our other articles on the site.

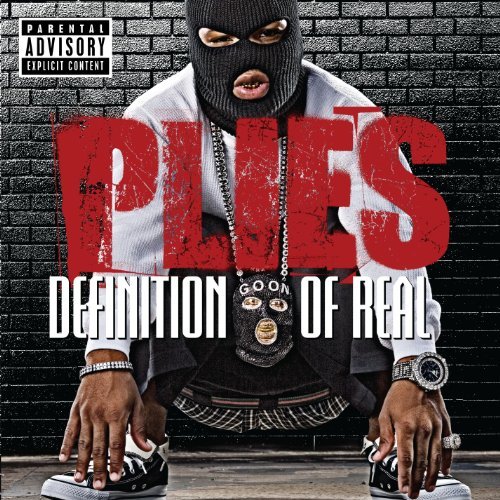

![Plies Definition Of Real [Album Stream]](http://www.playthishiphop.com/wp-content/uploads/2014/01/plies-dlrnl.jpg?x34382)